Product

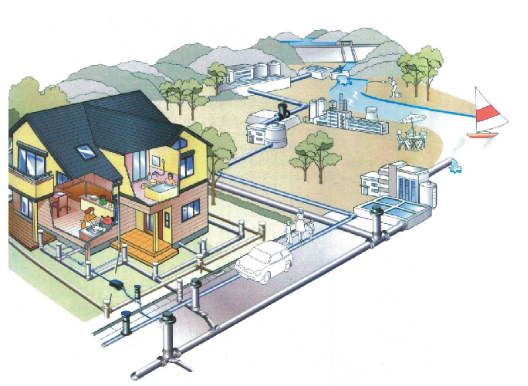

System introduction (Product Introduction)

Chuanlu Plastic Group' s piping system for underground drainage and sewerage is consist of HDPE double-wall corrugated pipe ( or PVC- U double-wall corrugated pipe) and dedicated plastic inspection well to make rain water and sewage drain without leak.

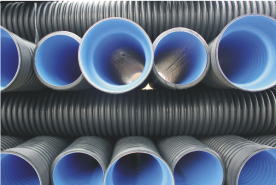

HDPE double-wall corrugated pipe is made of high density polyethylene with extrusion and special molding process. The inner wall of this new light pipe is smooth, and the outer wall is corrugated. This corrugated pipe is with the feature as light, strong of crush resistance and toughness, easy to install and has long service life. This kind pipe has been applied and acknowledged widely.

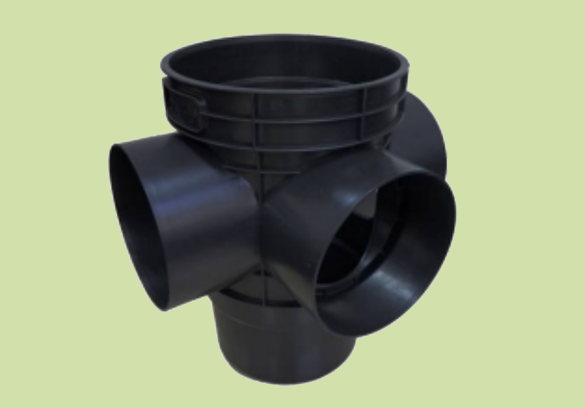

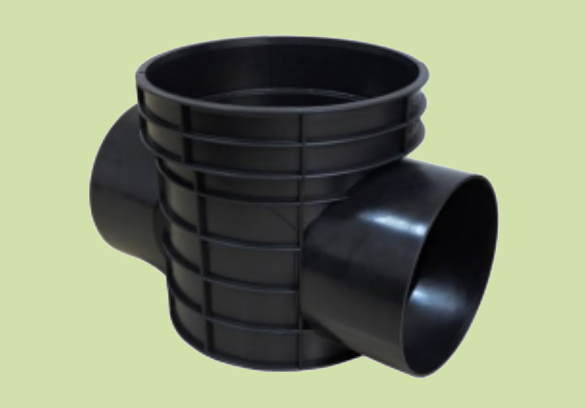

For plastic pipe and traditional brick or concrete inspection well , the difference between material and deflection coefficient causes connect or leaking, which is always a difficult problem for the industry. In order to solve this problem, we research and develop plastic inspection well. This product is made by injection molding, connecting wit h soft rubber ring and HDPE double-wall corrugated pipe, which has

controllable quality and specifications, available for resolving connector and opening leaking, thus reducing pavement settlement and improving road quality. Plastic pipe for drainage and sewerage complies wit h energy saving and emission reduction policy and can prevent groundwater resources from pollution, so it has great social benefit.

Application Area

municipal drainage and sewer age

Fields and gardening irrigation and drainage out side building under ground drainage mine & channel ventilation and drainage Communication cable and optical cable protective sleeve Road and play ground leakage and drainage | |

Performance characteristic of HDPE double-wall corrugated pipe

Comparing to traditional concrete pipe, HDPE double-wall corrugated pipe is a kind of flexible pipe, which has excellent chemical stability, aging resistance and environmental stress crack resistance. Its major performance characteristics are as follows:

1.Strong resistance to external pressure

The outer wall is unique corrugated annular structure which has high ring stiffness, increasing the resistance of pipe against the soil load. In comparison to traditional pipe, HDPE double-wall corrugated pipe has remarkable advantage.

2.Low coefficient of friction resistance and high flow

The inner wall of HDPE double-wall corrugated pipe is smooth, so the friction resistance is low. Comparing to the concrete pipe of the same diameter, its flow is higher. In other words, under the same flow requirement, you can use HDPE double-wall corrugated pipe that with smaller diameter.

3.Easy to install

The HDPE double-wall corrugated pipe is light, easy to handle and connect. So it is easy to install and maintain. Under limit duration and poor condition, its advantage is more remarkable.

4.Strong resistance to low temperature shock

The embrittlement temperature of HDPE double-wall corrugated pipe is -60℃, having strong resistance to shock. When install under general low temperature (above -20℃), it’s not necessary to use special protective measures, thus easy to install in winter.

5.Excellent chemical stability

The molecular of HDPE has no polarity, so the chemical stability is good. The soil, electricity, acid/alkaline factor in the general use conditions won’t damage the pipe, and no bacteria, no scaling, so the circulation area will not decrease over time.

6. Long service life

Avoiding direct exposure to ultraviolet rays from the sun, the service life of HDPE double-wall corrugated pipe is up to 50 years.

7.Good wear resistance

Germany has proved by tests that the wear resistance of HDPE is even four times higher than steel pipe.

8.Appropriate deflection

A certain length of HDPE double-wall corrugated pipe allows slight deflection, not influenced by uneven settlement of the ground to a certain extent. It can be laid directly in the slightly bent trenches without pipe fitting.

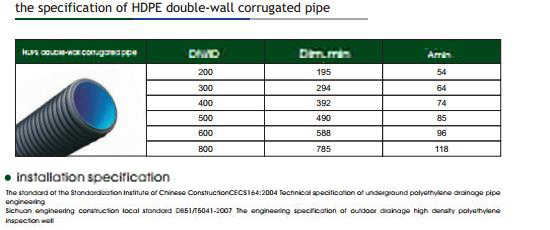

The specification of HDPE double-wall corrugated pipe

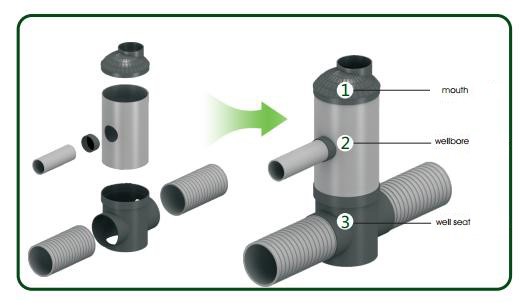

Plastic inspection well structure chart